359

359  108

1081. Introduction: FP Ensures Scientific Accuracy, AI Enables Intelligent Efficiency

In the previous seven articles, we clarified the core strengths of the True FP Algorithm:

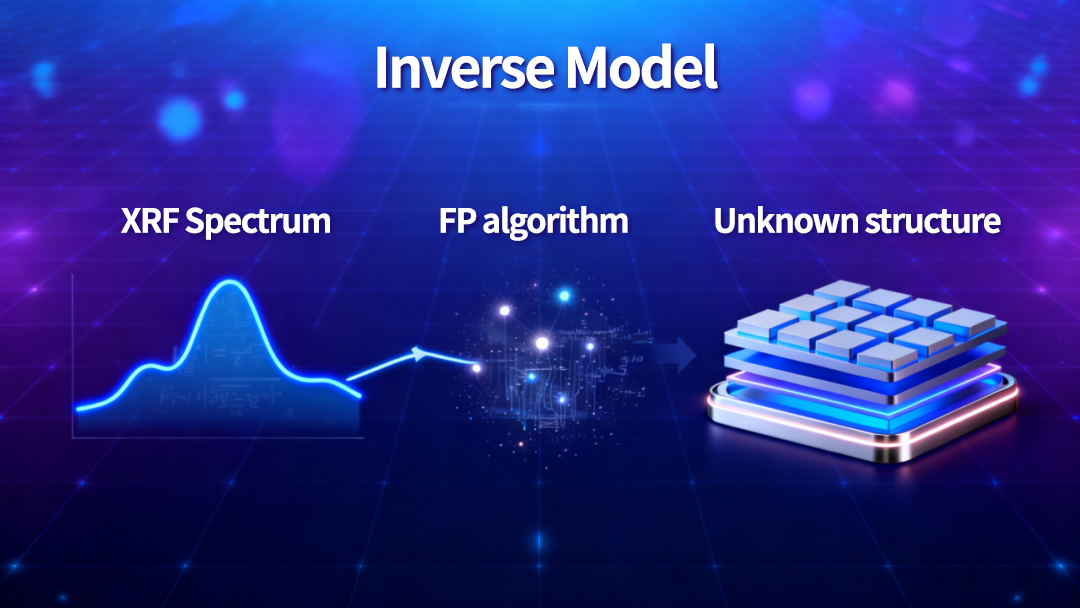

• It can forward-model spectra (structure → spectrum)

• It can invert spectra (spectrum → structure)

• It understands multi-layer coatings, alloy systems, and complex absorption effects

• It can infer the true structure of unknown/blind samples

FP has already brought XRF from"measuring peaks" into the era of understanding spectra.

Meanwhile, industry demands are evolving toward:

• more automation

• faster speed

• increasing sample complexity

• less manual parameter tuning

• Less dependence on expert operators

• automatic recognition of abnormal structures and fraud patterns

This leads to a natural requirement:

Can XRF become not only more accurate, but also faster, more automated, and more intelligent—without sacrificing scientific correctness?

The answer is FP + AI.

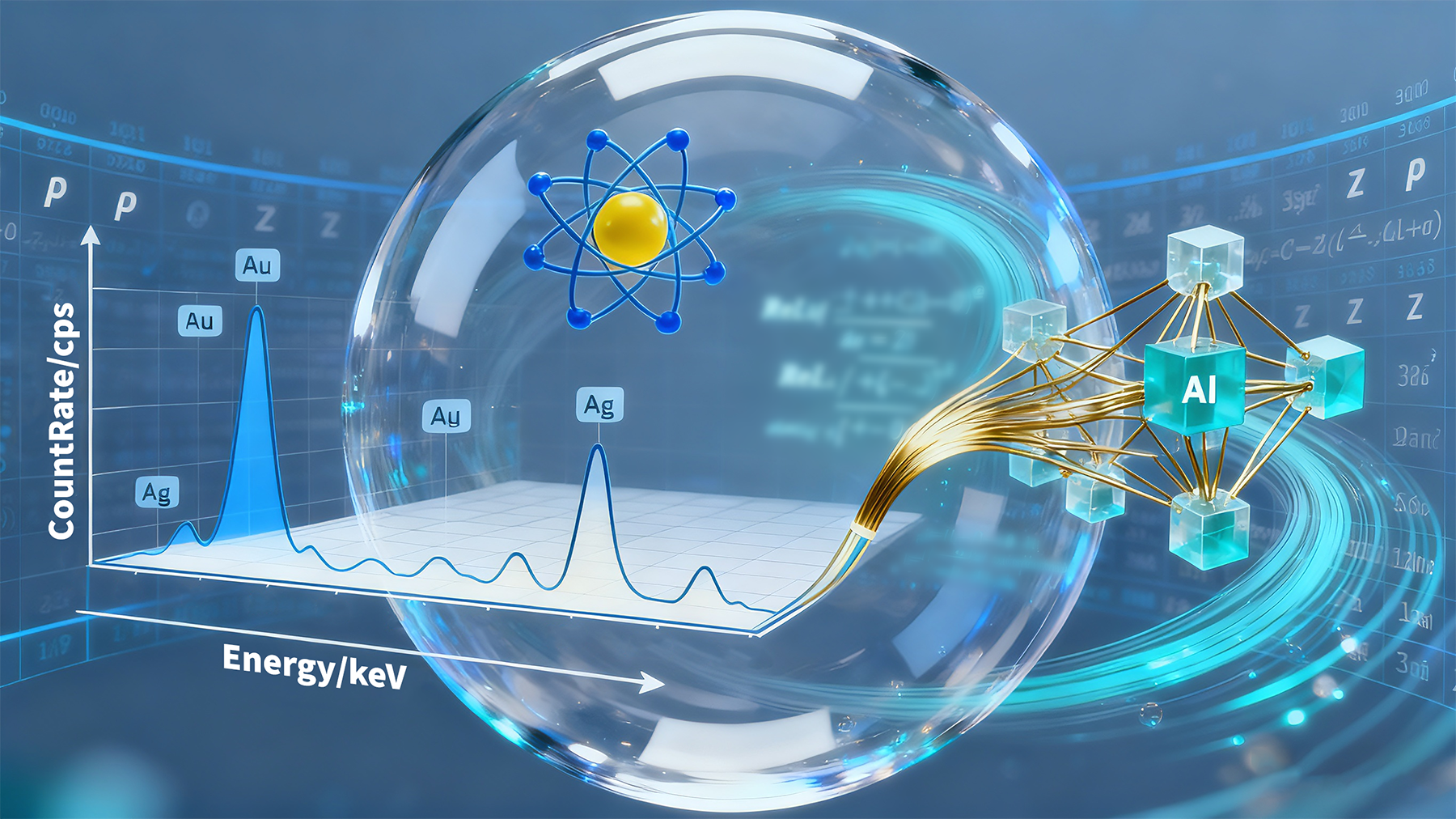

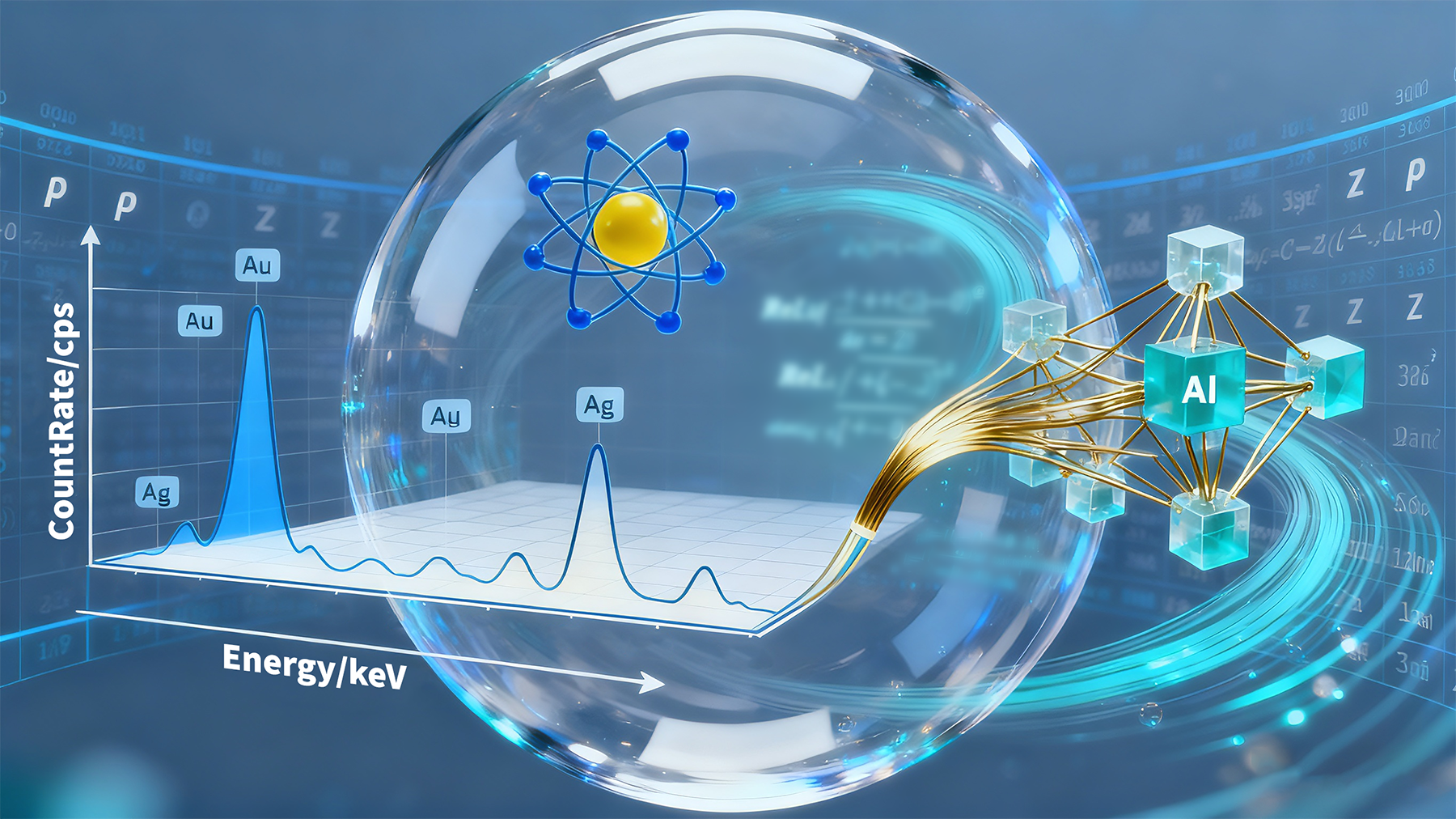

2. FP Is the Physical Engine; AI Serves as an Enhancement Module

✔ FP performs physical modeling and determines whether a structure is physically correct.

✔ AI performs pattern recognition to help FP become faster, more accurate and more automated.

AI does not replace FP.

AI does not make final judgments.

AI only assists FP by:

• providing better initial parameters

• narrowing the search space

• accelerating inversion

• identifying abnormal spectra

• helping the system learn over time

In short:

FP is the brain,and AI is the accelerator.

The future of XRF is not AI replacing FP, but AI amplifying FP.

3. Deployable FP+AI Architecture

To apply FP+AI in XRF, it must be clear which parts run locally and which run in the cloud.

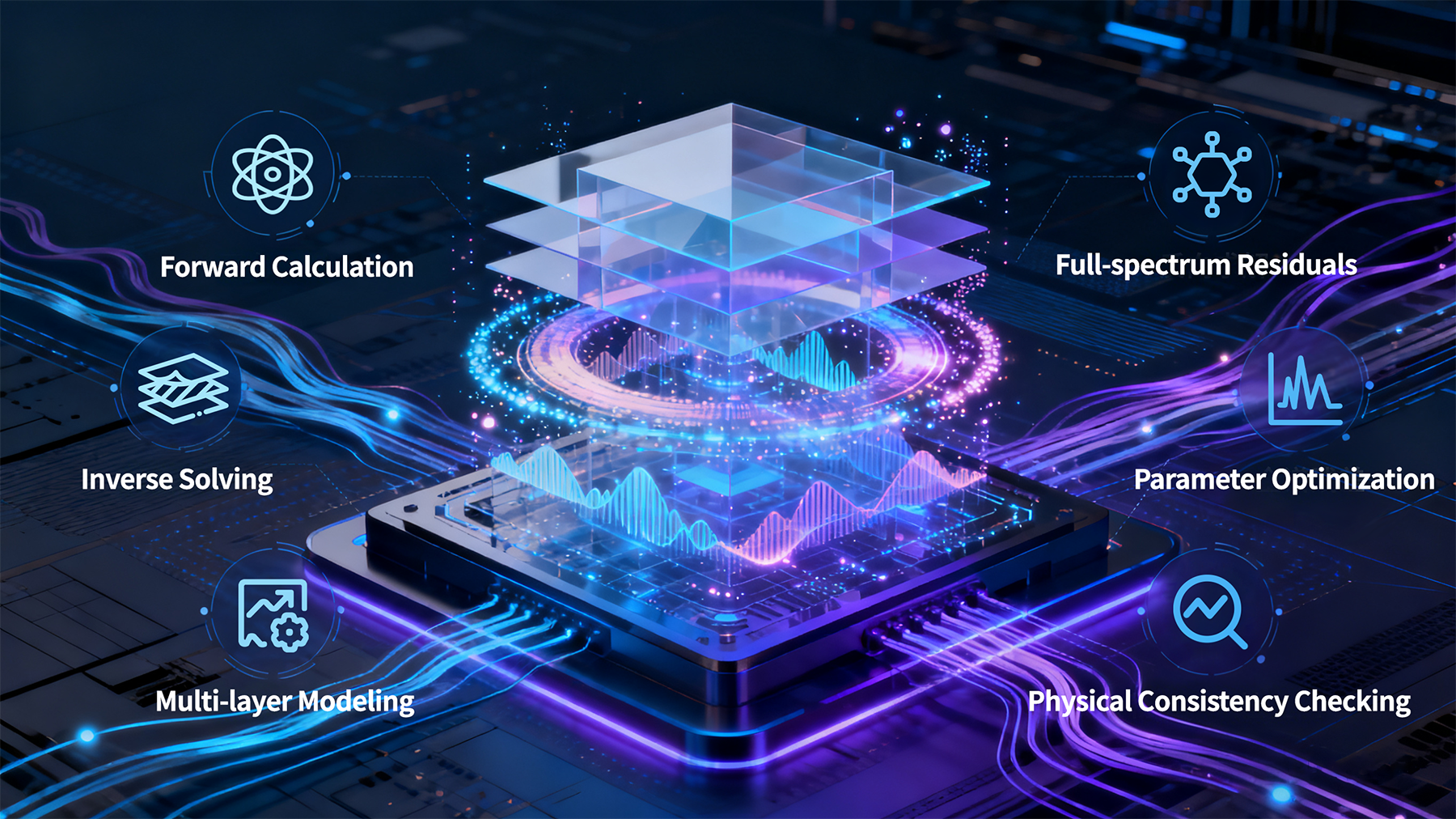

(1) On-Instrument (Local) Execution

① FP Physical Inversion Engine (Core)

• forward calculation

• inverse solving

• multi-layer modeling

• full-spectrum residuals

• parameter optimization

• physical consistency checking

These must run locally because:

• real-time performance is required

• traceability is required

• computation must be bound to instrument hardware

• measurement data must not rely on external networks

② Lightweight AI models(Embedded )

These models are very small — only a few hundred KB — and require no GPU.

They include the following three types:

a. Layer Predictor

Uses shallow neural networks or XGBoost to recognize spectral features and output:

“Is this likely a 1-layer, 2-layer, or 3-layer structure?"

Purpose:

→ avoid FP blind-searching from 1 layer upward

→ start FP near the correct layer number

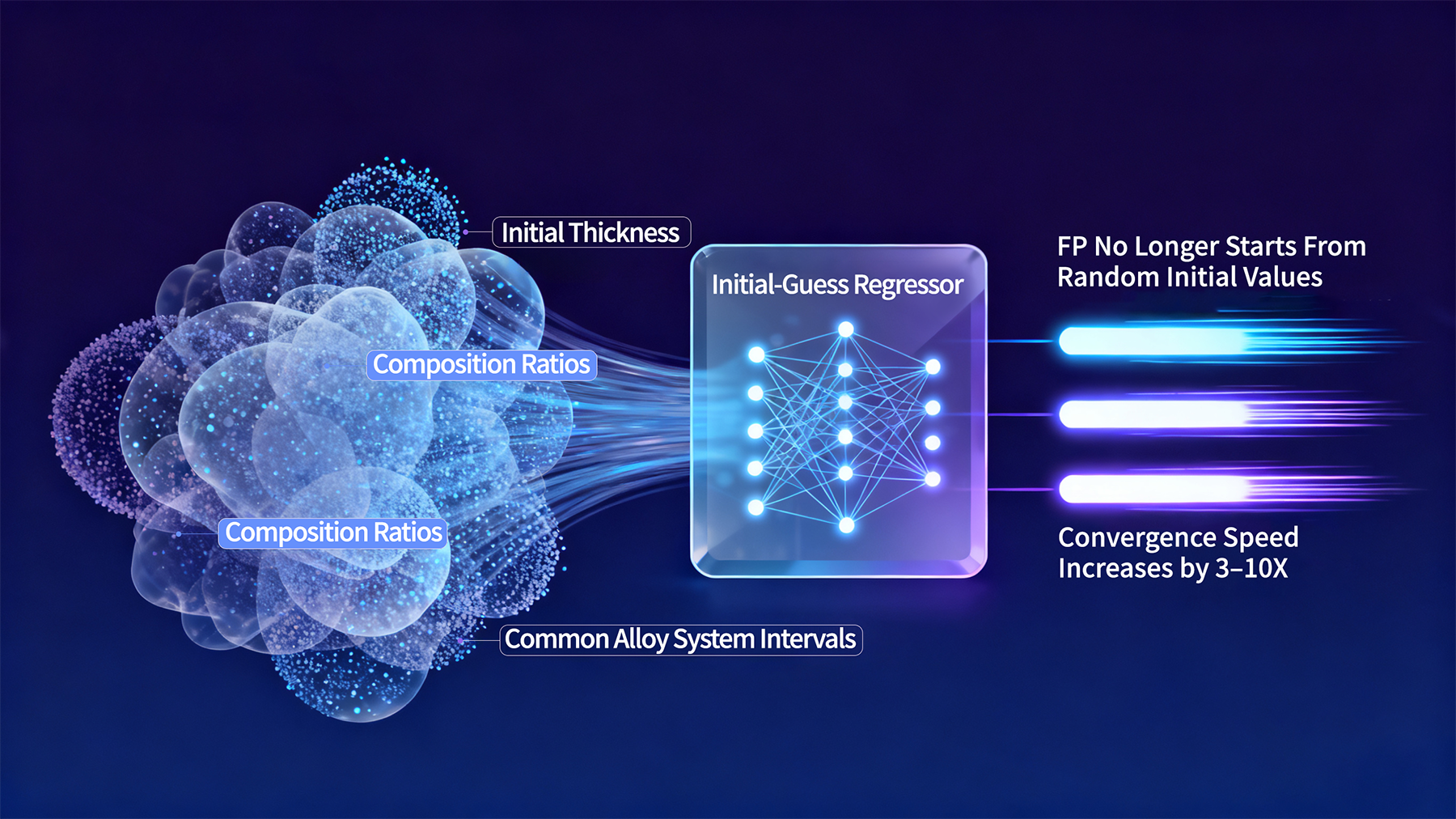

b. Initial-Guess Regressor

Learns from historical FP inversion data to estimate typical ranges of:

• initial thickness

• composition ratios

• common alloy system intervals

Purpose:

→ FP no longer starts from random initial values

→ convergence speed increases by 3–10X

c. Anomaly Detector

Used to determine:

• whether the sample is improperly positioned

• whether detector noise is too high

• whether the X-ray source has weakened

• whether suspicious spectral patterns appear (e.g., fake gold, treated gemstones)

Purpose:

→ avoid non-physical data in advance

→ improve the stability of FP inversion

(2) Cloud-Side Training (Not Involved in Real-Time Detection)

The cloud is suitable for:

• AI model training (based on large amounts of FP-inverted physical ground truth)

• model upgrading

• large-scale spectral clustering

• origin-estimation model training (gemstone direction)

• continuous expansion of the industry-wide"spectral knowledge base"

After training, updated AI weight files (within a few MB) are delivered to the instrument through software or firmware updates.

The cloud does not participate in real-time computation and does not affect the determinism of on-site detection.

4. How FP+AI Improves Precious Metal Alloy Detection

FP itself can already solve all computational problems for precious metal alloys (K-gold, Au–Cu, Au–Ag–Cu systems).

However, adding AI can significantly enhance overall performance.

(1) Intelligent Recognition of K-Gold Types (K-yellow / K-red / K-white)

AI can recognize spectral characteristics such as:

• background slope

• Cu-to-Au ratio tendencies

• Pd/Ni absorption differences

Then it tells FP:

“This is likely K-white, more likely an Au–Pd–Ni alloy model."

This prevents FP from trying many possible models.

(2) Spectral Recognition of Fake Gold (Re / W / Sb / Ge / Bi)

FP can separate peaks, but AI can recognize the patterns, including:

• characteristic noise patterns of fake gold

• abnormal absorption tails of Re/W

• weak-peak patterns of Ge/Bi

• Sb/Bi combinations used for"weight adjustment"

Effect:

→ FP provides the true composition

→ AI provides the suspicion alert

(3) Recognition of Alloy Manufacturing Processes

Different manufacturing processes produce distinct spectral differences:

• cast K-gold vs electroformed K-gold

• ancient-style gold vs modern hard gold

• 3D hard gold vs traditional metals

• diffusion K-gold vs single-alloy gold

AI can learn these patterns from large amounts of spectral data and help FP determine:

“This is an alloy body, not a plated structure."

This makes detection more automated and more intelligent.

5. The Future Role of FP+AI in Gemstone Detection

Gemstone analysis also benefits from the FP+AI architecture.

Why?

Because gemstone identification relies heavily on:

• trace elements (Cr, V, Fe, Ti, Ga, Mn, Ni)

• elemental ratios (e.g., Cr/V, Fe/Ti)

• origin-related characteristics (geological fingerprints)

• treatment indicators (heating, diffusion, filling)

Advantages of XRF:

• XRF can directly measure these chemical fingerprints.

• FP makes the chemical fingerprints more accurate (by removing absorption effects).

• AI recognizes the patterns within these fingerprints.

Therefore, FP+AI provides the following capabilities in gemstone detection:

(1) Natural vs Synthetic (AI Classification)

FP → provides accurate elemental compositions

AI → classification model determines:

• natural sapphire vs synthetic sapphire

• natural emerald vs hydrothermal emerald

• natural spinel vs synthetic spinel

(2) Origin Estimation (AI Clustering + FP Fingerprint Values)

FP provides accurate trace-element values.

AI performs clustering and confidence evaluation.

Applicable to:

• ruby (Myanmar / Thailand / Mozambique)

• sapphire (Sri Lanka / Madagascar)

• emerald (Colombia / Zambia)

(3) Treatment Identification (AI Recognizes"Treatment Signatures" )

Examples:

• diffusion-treated sapphire → increase in Ti

• fracture-filled emerald → presence of Pb, Ba

• irradiated topaz → increase in Ce

• HPHT diamond → presence of Ni, Co

FP provides the data; AI recognizes the patterns.

6. The Final Form of FP+AI: An Intelligent Reasoning-Based XRF System

Future XRF systems (especially for precious metals and gemstones) will be able to:

• automatically identify sample types

• automatically infer the number of layers

• automatically estimate initial parameter ranges

• automatically perform inversion (FP engine)

• automatically detect abnormal data

• automatically determine fake-gold characteristics

• automatically classify gemstones as natural or synthetic

• automatically estimate origin

• automatically calibrate instrument status

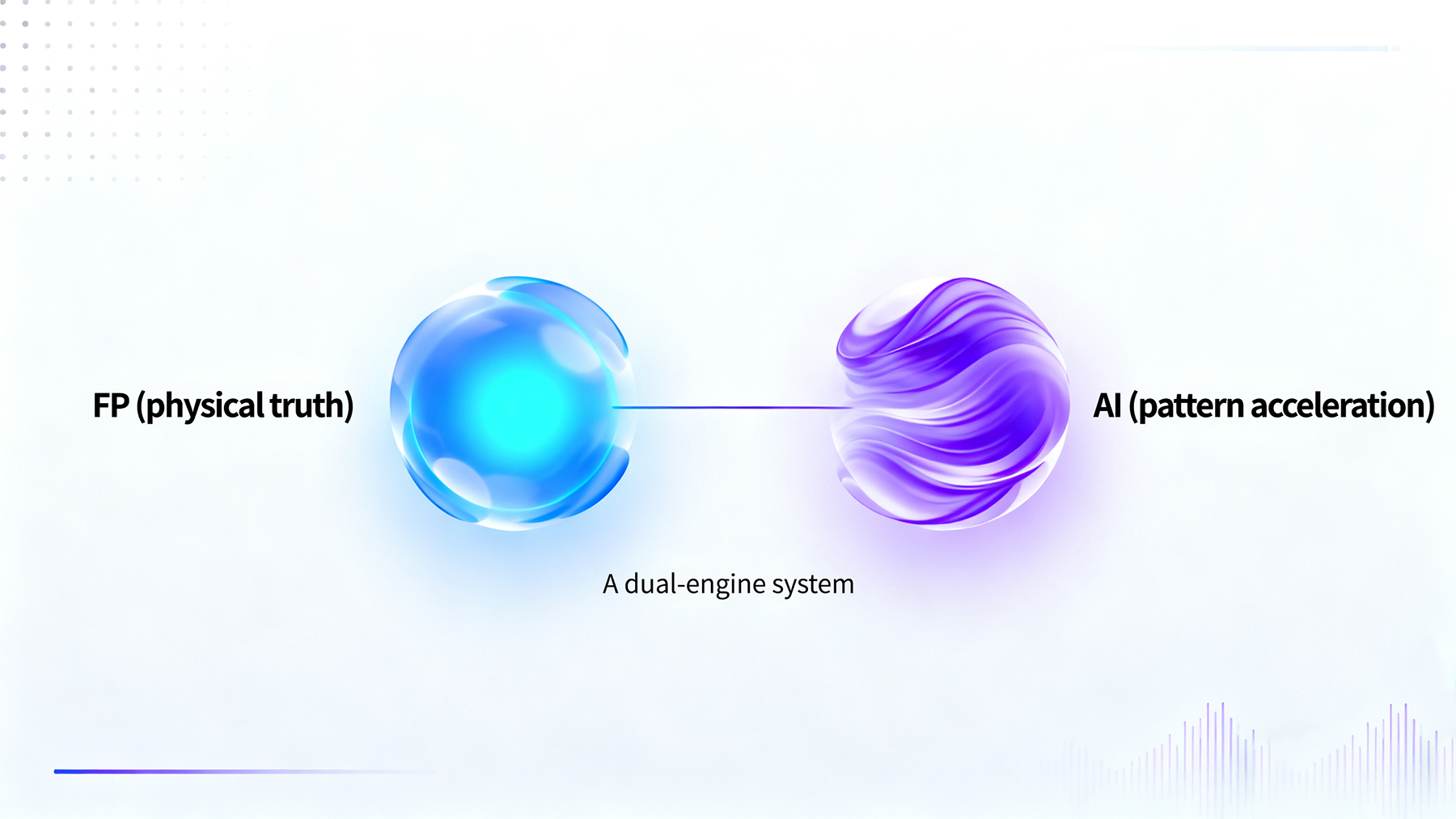

Eventually forming a dual-engine system of:

FP (physical truth) + AI (pattern acceleration).

This represents an"intelligent reasoning XRF" ,with the true ability to understand materials.

7. Conclusion: FP Provides Scientific Truth, AI Provides Scalability

• FP solves the question of whether it is physically true.

• AI solves the question of whether it can scale, automate, and become intelligent.

• FP + AI moves detection from manual reasoning to automatic reasoning.

The future detection system will be:

based on FP's physical modeling,

enhanced by AI-driven intelligent decision-making,

ultimately enabling XRF to learn, reason, and adapt.

-

-

-

Probe into Novel Gold-plated Jewelry2025-06-04

Probe into Novel Gold-plated Jewelry2025-06-04 -

XRF Secondary Programming - "Formula Editor"2025-03-23

XRF Secondary Programming - "Formula Editor"2025-03-23 -

-